"Supply Chain" is a term not many of us thought of before March of 2020. We did, however, enjoy getting what we wanted, when we wanted it. The pandemic changed all that.

"There is no automaker that has not been hindered in some way, shape, or form when it comes to sales because they just simply have no inventory," said Ivan Drury, Senior Dir. of Insights for Edmunds.com.

"Whatever becomes the hot toy of the season in the next month or two may not be there in huge quantities," said Steve Pasierb, President and CEO of the Toy Industry Association.

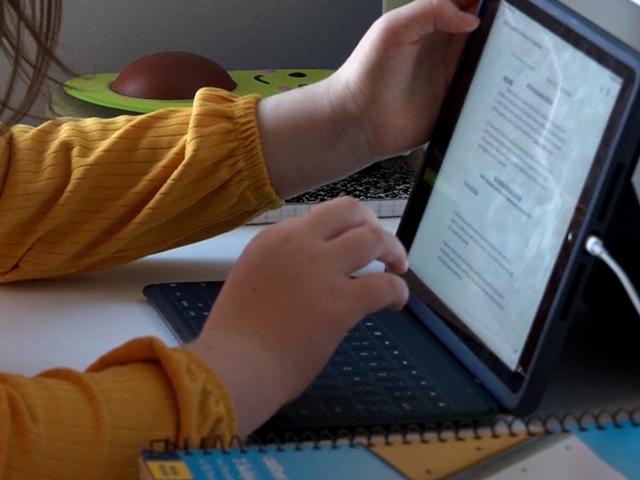

Some of the worst backups are happening in what's called durable goods: appliances, laptops, and furniture. That's because the pandemic changed spending habits.

"People said, 'Well if I can't go on vacation, I'll get a bicycle. Or I'll repaint the house, put in new curtains.' And then they found paint was on backorder, curtains were on backorder because everybody was trying to buy these durable goods that everyone else wanted," explained economic consultant Bill Conerly.

Many businesses also cut back at the outset, expecting a major slow-down in sales.

"Then came summer of last year. Consumer spending was there and all these businesses tried to turn around real fast, but it's hard to turn around real fast," Conerly told CBN News.

Then, according to Conerly, came the perfect storm.

"The Suez Canal got clogged, a couple of the seaports in China were closed because of COVID, the hurricane took down natural gas production, which is a feedstock for a lot of chemicals," he explained.

Still, Conerly believes the biggest overall interruption came in the workforce.

"The shortage of workers is common all around the country, and as a result, businesses that want to increase their production, want to serve their customers better, want to stock up on inventory, they cannot find the workers," Conerly said.

This affects each level of the domestic supply chain; from factories to the trucking industry to distribution centers. And international goods can't get here because of a major backup at our ports. Shipping containers are waiting to unload for up to eight days, due in part to labor shortages at docks.

Experts and businesses alike don't see this ending until 2022. For some industries that's meant shutdowns. GM, Toyota, and Nissan have all paused production because of a shortage of computer semiconductor chips used in a large number of car parts.

"Some automakers are reworking their vehicles to need fewer chips, certain options aren't being offered, but it's not been enough to curb all of these issues," said Drury.

Other industries are forced to pay up to three times more for supplies than in the past, and still, barely get enough to keep the doors open.

Oakley Monument Company has seen a major surge in business due to COVID-related deaths, but grieving customers are waiting months for memorials.

"We're lucky if we're able to get a quarter of what we need for our order once a month...Stuff that used to cost us $9,000 to get shipped is up anywhere in the twenty-thousands just to get it shipped here and then they also tack on a tariff as well," said Alison Leisten, a sales associate for Oakley Monument Company.

Alignable, a small business network, is helping companies pivot. A major step forward has been simply connecting business owners to others in their industry.

"We actually have created groups. So an industry can come together and share ideas, so we'll have an industry group just for florists. They can actually share ideas with others about where are they looking to get supplies, how are they filling part-time roles at their companies, and things like that," Alignable CEO & Co-Founder Eric Groves told CBN News

That way of thinking allowed Mark Patterson, co-founder of Civilized Coffee, to get around some supply chain issues.

"What we've been doing is buying large lots, full containers of coffee, bringing them back to our warehouse and then, we've just said, 'reach out to us,' and we have a lot of relationships where we can sell off smaller lots to these smaller roasters around the country," Patterson explained.

Meanwhile, consumers are feeling the result of all this in their wallets.

"The classic definition of inflation is too many dollars chasing too few goods. We've got a lot of dollars that people are trying to spend, {but} we have not increased our production capacity," said Conerly.

He predicts this could lead to a Boom and Bust Economy similar to the late '60s and 1970s. Simply put, that would mean high inflation, followed by a tightening of monetary policy by the Federal Reserve, resulting in a recession. Then, they would hit the gas again, causing more inflation.

Conerly's advice to businesses comes straight from the Old Testament.

"There's this old dream that the pharaoh had, and Joseph said, 'You need to use the good years to prepare for the bad years,' and that applies to businesses today. They need to take advantage of the good years while they're here, but they need to be ready for the bad years because we're going to have a couple of recessions, I think, in the next five to ten years," Conerly warned.

With the holiday season upon us, experts say retailers are doing their best to prepare for the rush, but there's only going to be so much they can do to stock their shelves. So whether you typically shop early or last minute, now is the time to start marking items off your list.

Did you know?

God is everywhere—even in the news. That’s why we view every news story through the lens of faith. We are committed to delivering quality independent Christian journalism you can trust. But it takes a lot of hard work, time, and money to do what we do. Help us continue to be a voice for truth in the media by supporting CBN News for as little as $1.

Subscribe

Subscribe Follow

Follow CBN.com

CBN.com

Support CBN News

Support CBN News